-

Enzymatic Extraction

Specialist in enzymatic extraction

A clean process, solvent-free

Our know-how is expressed in the creation of enzymatic mixtures adapted to plants and extraction targets. The use of enzymes in our extraction process allows to obtain original natural ingredients from different types of raw materials: plants, algae, mushrooms...

INDUSTRIAL POSITIONING

> Removal of organic solvent in the ingredient manufacturing. A mild and environmental friendly process from the sourcing to the end product.

> Valuation of vegetable raw materials: seeds, leaves, stems, roots, flowers, fruits, vegetables... We can treat all types of vegetable biomass and we apply ourselves to valorize the agricultural, agri-food and forest co-products in order to favor the circular economy.

> Extraction without organic solvent: water is our only extraction solvent!

TECHNICAL KNOW-HOW

> Deep knowledge in enzymatic engineering and ability to implement it.

> Ten-year experience in the developement of tailor-made ingredients.

> The complete development of an ingredient from sourcing to marketing (more information).

> The characterization and activity tests of the ingredients obtained from the process.

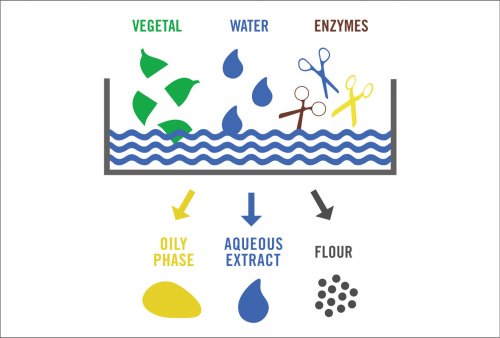

> Plant biorefinery: a plant, three potential products. Vegetable oil, aqueous extract and cake: a raw material, a clean process, three fractions to be valued.

ENZYMATIC COMPOSITION

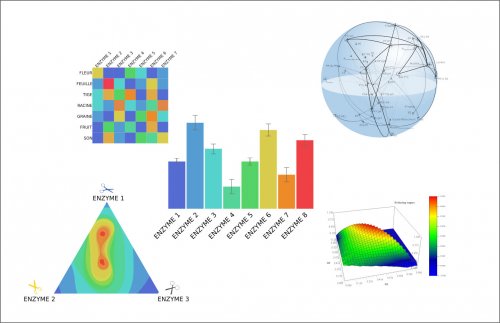

> The design of specific enzymatic mixtures adapted to the biomass and extraction objectives.

> A perfect knowledge of our enzymatic mixtures coupled with predictive statistical tools makes it possible to identify extraction synergies and to design mixtures adapted to each plant material.

> Our enzymatic mixtures are certified non-GMO and are food grade. This allows you to obtain certifications requested by the market: COSMOS, NATRUE... HALAL or KASHER certifications are available on request.

EXTRACTION PROCESS

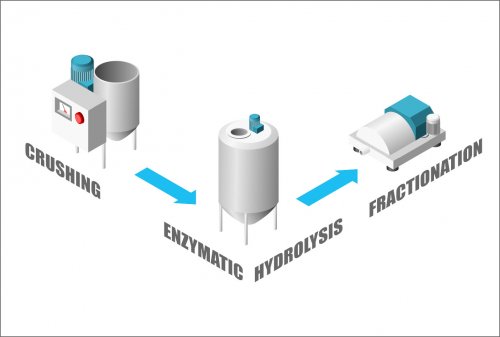

The extraction process consists of three parts:

> Grinding, to reduce the size of the plant and increase the contact surface available for the enzymes.

> The enzymatic reaction takes place in a tank stirred and thermostated in the presence of water.

> Centrifugal separation is the last step of the extraction process: it allows to obtain an aqueous extract, a vegetable oil and a cake.

These three fractions are then worked separately to ensure the microbiological quality and stability and to increase the quality, purity or concentration of certain elements (oligosaccharides, peptides, amino acids, minerals...).